Turbulent flow

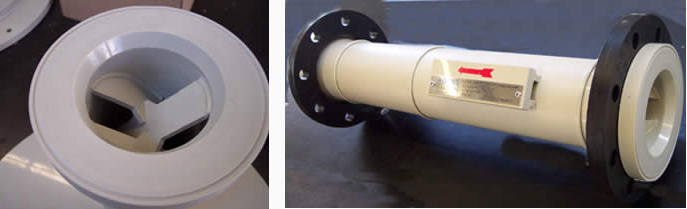

The AGENS AMX-3 generates counter-directional rotation vortices. It is suitable for the simplest mixing applications, and its very reasonable

price-performance ratio makes it particularly attractive. The mixer is insensitive against solids and is particularly suitable for the waste water industry.

We offer this mixer in the following production series:

| AGENS AMX-3 Static Mixer | Material: | Mixing elements pipe: | Polyethylen | |

| Standard series with three (3) mixing elements |

Flanges: | Polyprophylen with carbon steel inlay |

||

| All product parts in PE. In detail: | Pipe classification: |

DIN 8074/8075 | ||

| Pressure stage: | SDR 11 (PN10) | |||

| Flanges: | drilled to ANSI 150 lbs | PN 10 (former DIN 2642) |

| DESIGNATION | OUTSIDE DIAMETER | WALL THICKNESS | LENGTH |

| AGENS AMX-3-PE-2" | 63 mm | 5,8 mm | 300 mm |

| AGENS AMX-3-PE-2 1/2" | 75 mm | 6,8 mm | 400 mm |

| AGENS AMX-3-PE-3" | 90 mm | 8,2 mm | 500 mm |

| AGENS AMX-3-PE-4" | 110 mm | 10,0 mm | 600 mm |

| AGENS AMX-3-PE-6" | 160 mm | 14,6 mm | 900 mm |

| AGENS AMX-3-PE-8" | 200 mm | 18,2 mm | 1100 mm |

| AGENS AMX-3-PE-10" | 250 mm | 22,7 mm | 1500 mm |

| AGENS AMX-3-PE-12" | 315 mm | 28,6 mm | 1800 mm |

| AGENS AMX-3-PE-14" | 355 mm | 32,2 mm | 1900 mm |

| AGENS AMX-3-PE-16" | 400 mm | 36,3 mm | 2000 mm |

| Calculation of pressure drop for turbulent flow |

| Pressure drop in mbar = 0,048 * (density in kg/m3) * (flow velocity pipe m/s)2 ∆p [in mbar] = 0,048 * ρ [kg/m3] * v2 [m/s]2 |