Static Mixers for extrusion

The high frictional forces between the channel inner wall and the polymer flow present the main problem in the extrusion of thermoplastics. Because of these forces, the flow rate at the inner wall of the channel is practically equal to zero. In the middle of the channel, the flow rate increases correspondingly. This forms the typical laminary flow profile.

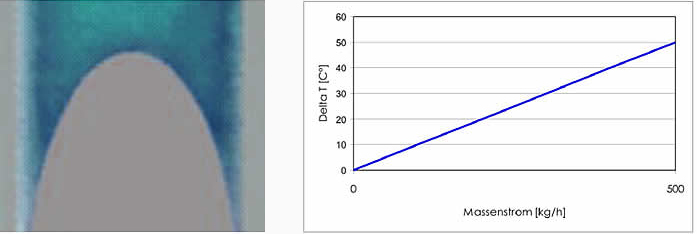

The associated diagram shows the temperature difference between the channel middle and wall for an LDPE extrusion. Differences of

up to 40°C in the polymer flow can occur for an increasing flow rate. The viscosity of the melt changes in relation to these temperature

differences, with the following productivity results:

• Poor and inexact extrudates

• Not possible to produce work results

• Defective master batch distribution, high operating costs

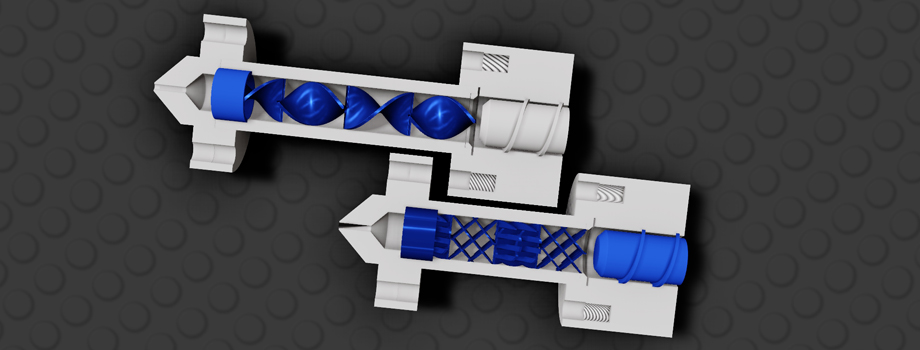

Solution: Static Mixer AGENS® AME-X

The AGENS AME - XR combines the procedural advantages of the AMX mixer with an extremely robust construction due to the use of high-grade materials. Fundamentally, we offer our customers individual solutions. We avoid connection rods or segmentation of mixer elements.

This provides the following advantages:

• Thermal and product-related inhomogeneities are eliminated

• Close extrudate tolerances due to homogenous polymer flow in the mould

• Optimal distribution for the master batch, thus reduced costs for this colorant

• Fundamental improvement in the mechanical properties of the extrudate

• Significant improvement in the extrudate surface

PVC or PC Polymers Susceptible to Shearing

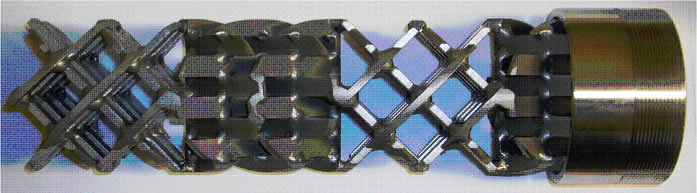

We can present a solution even for polymers such as PVC which are susceptible to shearing. The AGENS AME - WR has proven its performance in tough applications with these polymers.